More and more industries are cutting their materials with water jet methods over other industrial cutting methods. There are many advantages to cutting with water over methods such as laser or plasma cutting and as such, it is a becoming a more commonplace cutting technique in a wider range of industries.

Industries that rely on water jet cutting are home renovations, contracting, construction, mining, and aerospace. Even hobbyists and artists can benefit from water jet cutting methods.

What is Water Jet Cutting?

There are many highly durable materials that require industrial cutting methods in order to achieve precise cuts and smooth edges. However, due to the properties of some of these materials, cutting methods that utilize heat cannot be used as they will cause the material to melt or warp.

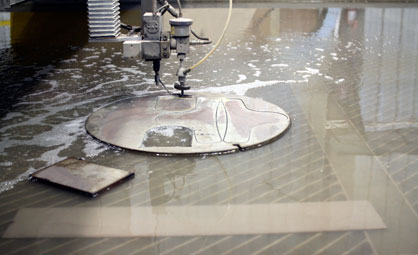

Water jet cutting is a means of applying a jet stream of water at a high velocity of 40,000 to 55000 psi to the material in question in order to render fine precise cuts with smooth edges.

In the water jet cutting process, there is a small orifice made with sapphire, ruby or diamond through which the water is shot after it has been combined with an abrasive substance.

The abrasive substance used is usually garnet as it is efficient and non-toxic. Some water jet cutting methods use aluminum oxide, but this is occurring less and less due to environmental awareness. Previously, water streams that were combined with aluminum oxide had to be disposed of after one use to a landfill. By using garnet or sand, the mixture can be used again and there is no toxic waste to dispose of.

What is Water Cutting Used For?

Water jet cutting is used for a wide range of projects. It can be applied to create unique and beautiful designs and shapes out of marble, granite or stone. It can also be effectively applied to heat sensitive materials that would melt and distort under the heat pressure of other industrial cutting methods such as laser cutting or plasma cutting.

Water jet cutting is an effective means of sizing tubes, cutting screens, rendering fine cuts and three-dimensional designs, and of achieving intricate patterns.

Materials that can be cut with water jet cutting include:

-

Steel

-

Stainless Steel

-

Aluminum

-

Carpet

-

Brass

-

Rubber

-

Plastic

-

Titanium

-

Stone

-

Marble

-

Granite

As cutting with water can ensure fine precision cuts, less expensive material goes to waste due to mistakes, warping, distortion or burring.

Water jet cutting can be applied to materials that range in thickness from 0.002” to 0.12”. The points of accuracy are high at up to +/-0.001. h., and the actual contact force of the cutting stream is low.

Cutting with water enables industries to expand on the services they offer and enables them to save money on materials that do not go to waste as a result of cutting mistakes.